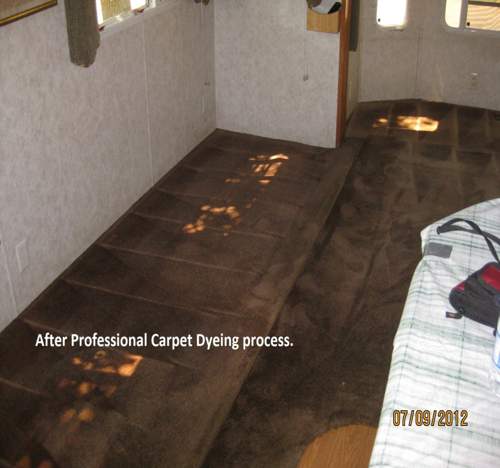

Carpet Dyeing Process

Dyemasters the rug colorists colorful carpets elite steam dye rite carpets texas steam team revive carpet full spectrum carpet dyeing the carpet chemist magic carpet inc.

Carpet dyeing process. Nylon carpet fiber is a good choice for all traffic areas because it is durable and static free maintains fiber height and resists soiling staining and mildew. The dye process can vary dramatically when it comes to giving carpet the rich colors and patterns that make it so popular. Spray jets are used to apply the dye on the carpet evenly in a continuous process moving forward and backward through the dye range. That said the process isn t the answer for every carpet.

It is done after the yarn is turned into a carpet. Post dyeing is divided into the following sub types. Most companies use a specialized dye that they spray onto the carpet and then scrub into the fibers to achieve an even look. Dye can be applied to the fibers before tufting after the carpet has been tufted and before the secondary backing is put on.

Carpet dying is intended to make a carpet look good for a while longer. Carpet dye is not a permanent solution to replacing carpets and should never be done on dirty or excessively worn carpets. Commercial dyes are chemically set and professionals can adjust the strength and development time of the carpet dye according to the carpet s thickness and material. On average carpet dyeing is a third the cost of carpet replacement 586 vs.

Nylon carpet fiber is the most popular fiber about 90 of residential carpets and 65 of all carpets. The carpet is then steamed to allow the dye to set onto the fibers. Dye carpet give your plush a fresh clean stain free reboot with the guidance here. Carpet fiber characteristics nylon carpet.

Compare prices from professional carpet dyeing services.